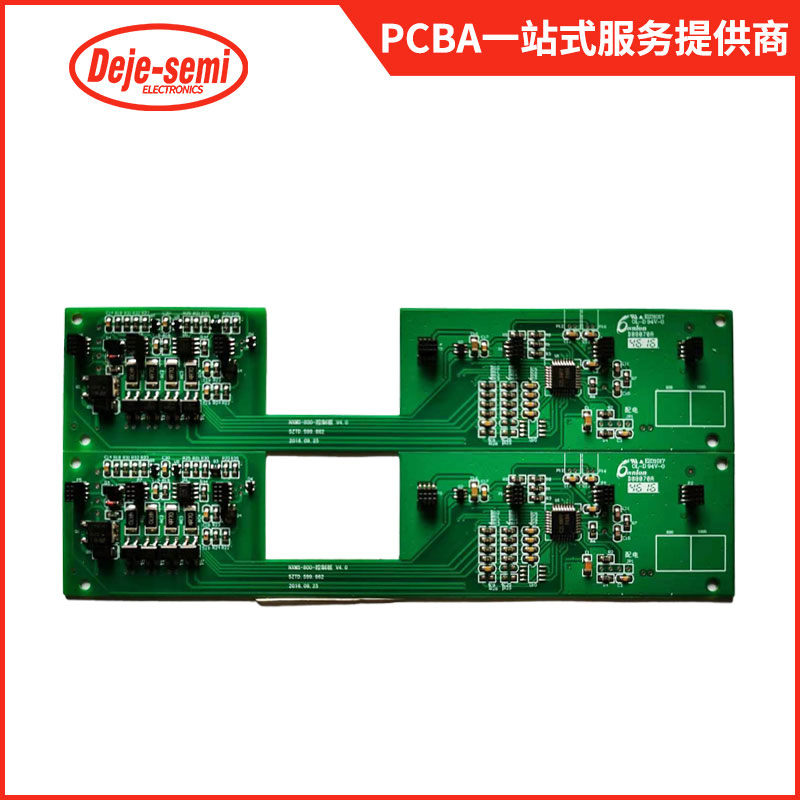

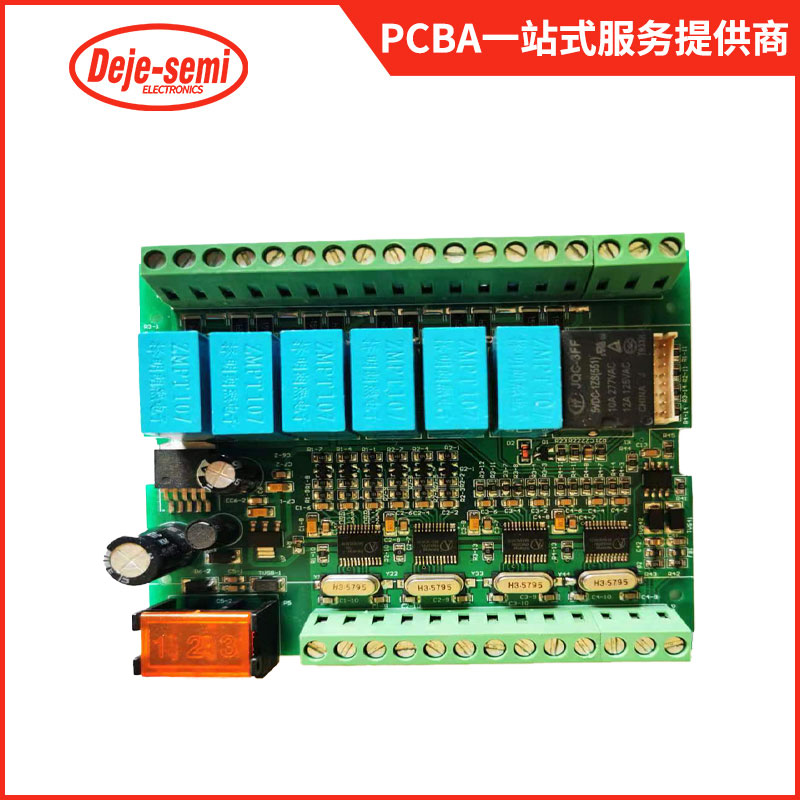

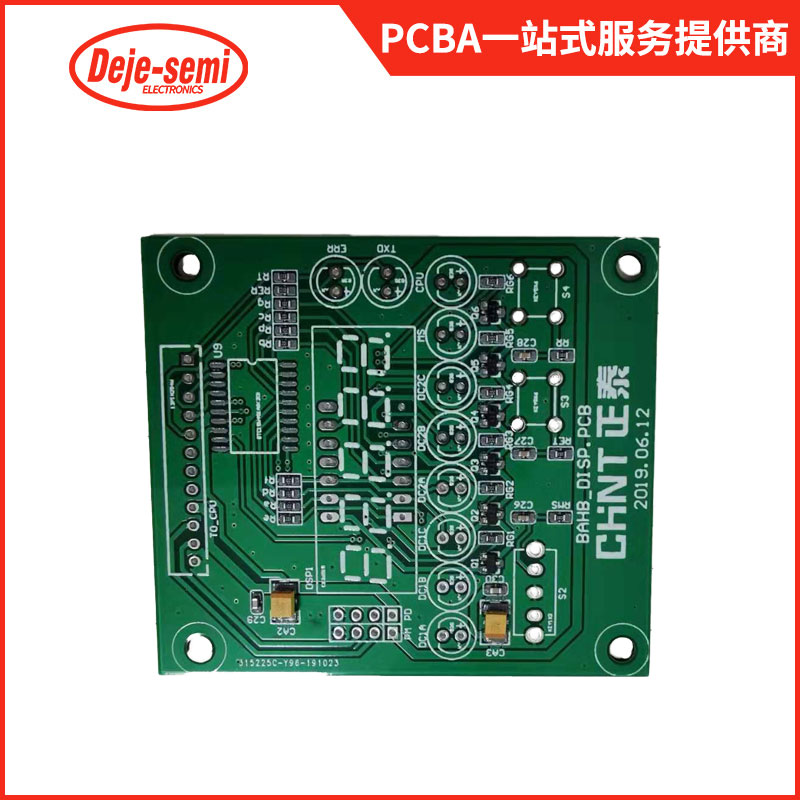

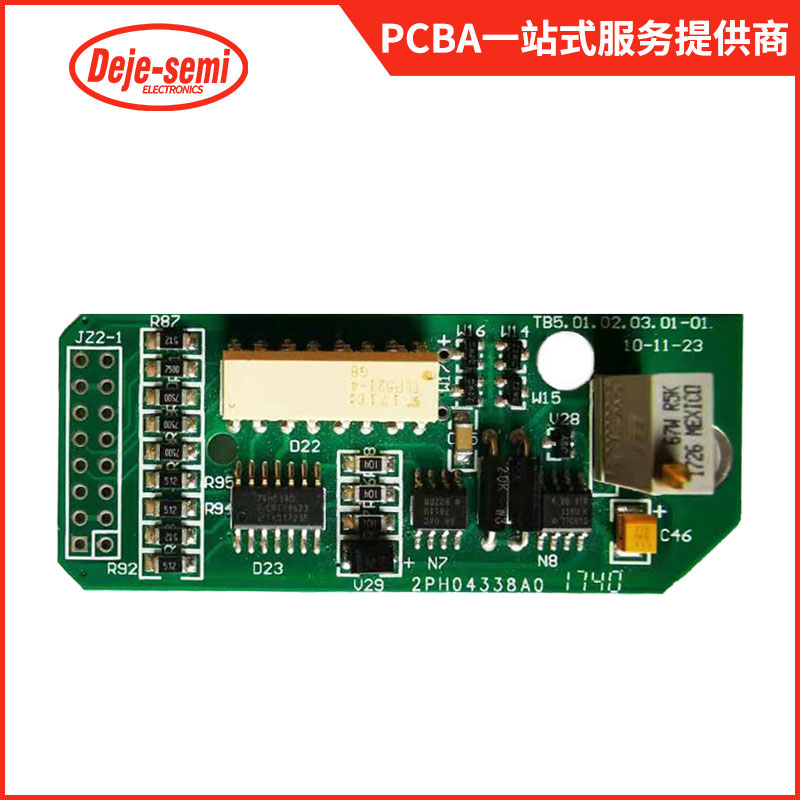

PCB making service&production process

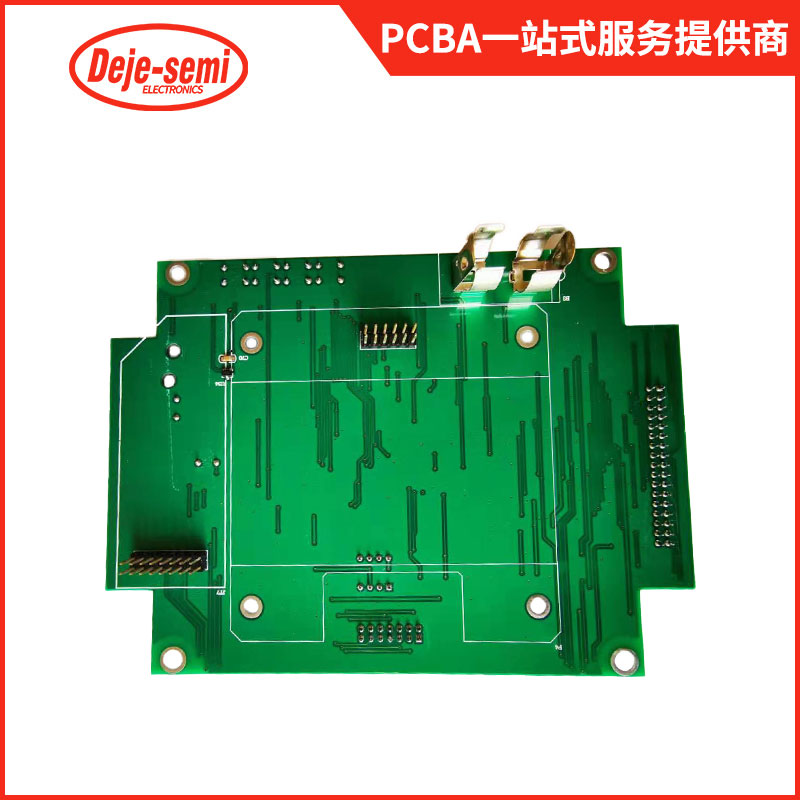

Zhejiang Dejie electronics has strategic cooperation with many PCB factories to deliver customers with the most efficient and affordable price. It can produce single, double sided and multi-layer PCB. Can provide impedance board, HDI board, blind hole board and other multilayer PCB board proofing, small batch production business.

Our advantages in making boards: We can make 1-40 layers of high-precision circuit board | First class suppliers of circuit board for four domestic automobile enterprises | Military industry cooperation unit

PCB board to be provided:

Gerber data, PCB manufacturing process requirements (plate thickness, copper thickness, solder mask color, silk screen color, surface treatment process);

PS: Impedance plate should provide impedance value.

PCB should be evaluated before making board:

1. Is GB data complete? Specific information such as plate making process requirements, impedance control requirements, etc;

2. Whether the process capacity meets the design requirements, including manufacturability, electrical measurement, maintainability, etc.

After PCB is made, we can provide:

Processed Gerber data, mesh file, panel file, impedance test report, PCB slice analysis report.

Our strengths:

PCB manufacturing service started in 2013, with the ability of rapid delivery and quality assurance, it can produce high-rise digital board, high Tg board, HDI board, FPC, rigid flex board, metal substrate, etc.

Delivery date of PCB flash board and sample:

The double-sided Allegro can be completed within 24 hours, and the multi-layer Allegro can be completed in 2-5 days;

Single / double sided (0.6-1.6mm FR4) delivery time: 3-4 days;

4-layer board (0.6-1.6mm FR4) delivery time: 5-6 days;

6-layer board (0.8-1.6mm FR4) delivery time: 7-8 days.

Software for PCB:

Software for converting PCB original file into GB data: Allegro, Protel99Se/AD, PADS, CAD.

Software for processing GB data: Genesis 2000、CAM350, etc.