<del id="u0s0c"></del>

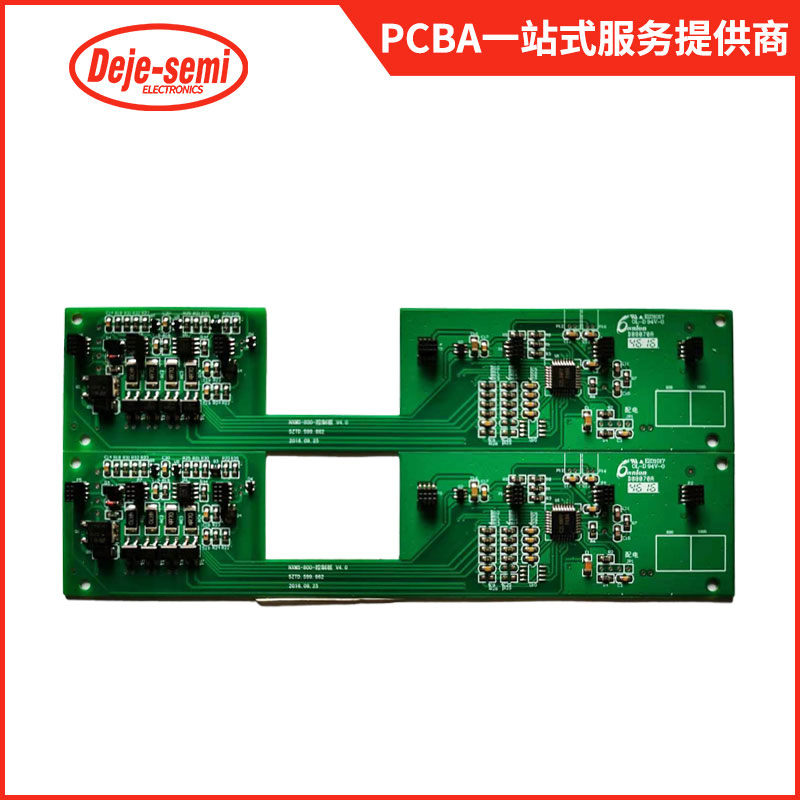

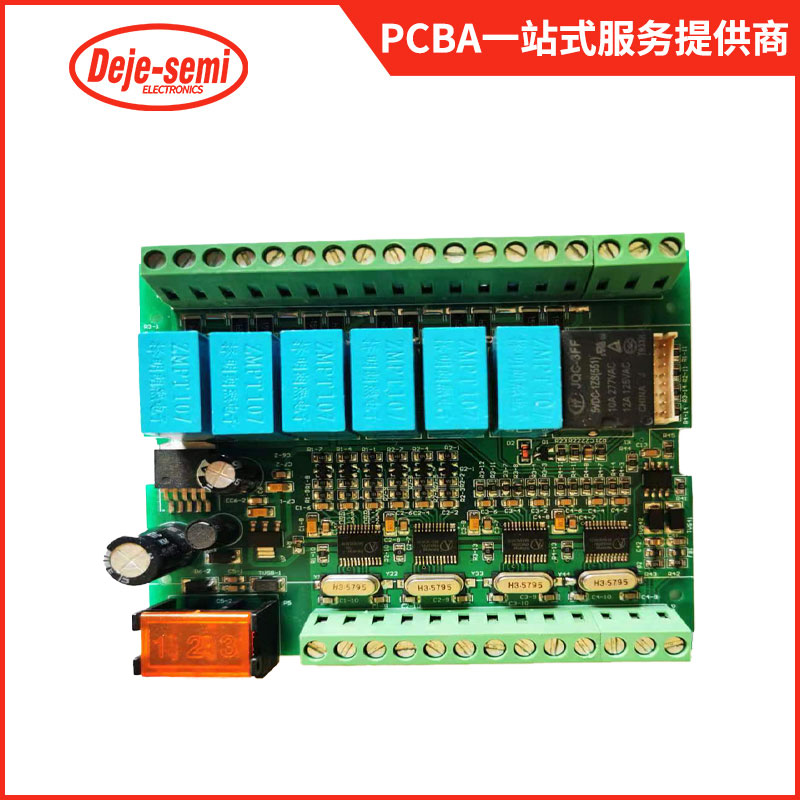

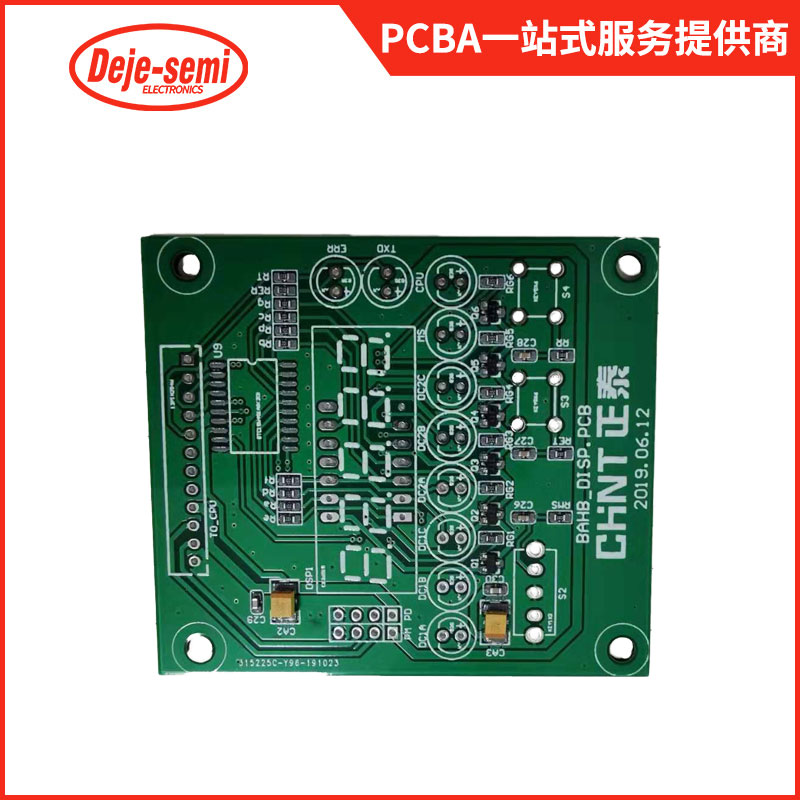

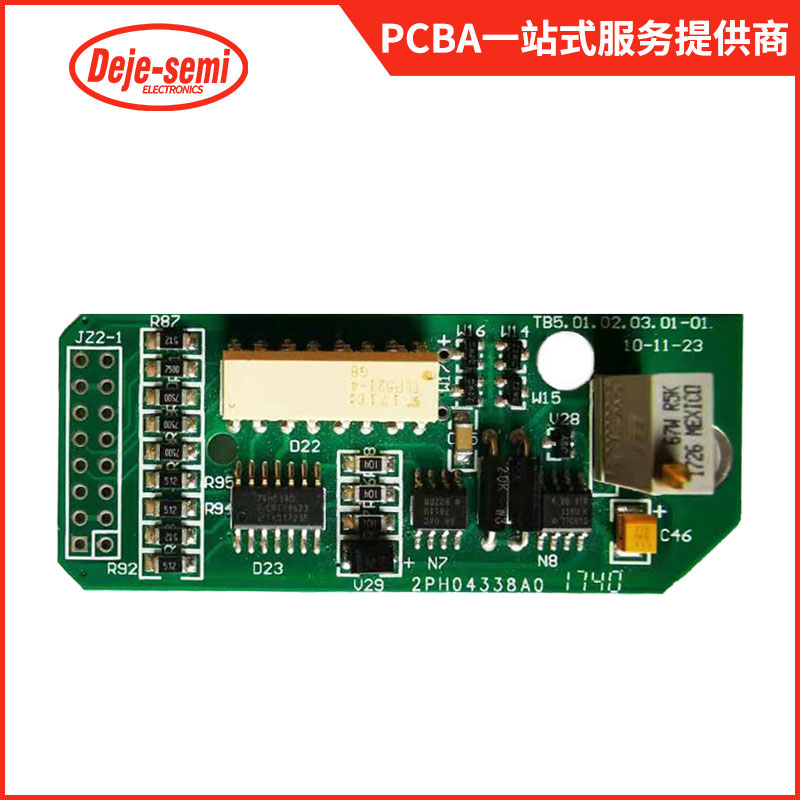

Zhejiang Dejie Electronic Technology Co., Ltd. is specialized in providing PCBA electronic manufacturing services, including upstream electronic components procurement to PCB production and processing, SMT placement, dip plug-in, PCBA testing, finished product assembly and other one-stop services. The company gives full play to its competitive advantages in scale procurement and quality control, and signs long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality of raw materials and stable supply, and transfer the preferential treatment to customers. Keeping the purchasing advantages of IC, resistor, capacitor, inductor, transistor and other components for a long time can greatly save the inventory cost of customers, improve the turnover efficiency of production and save time. At present, we provide PCBA processing services to customers all over the world.

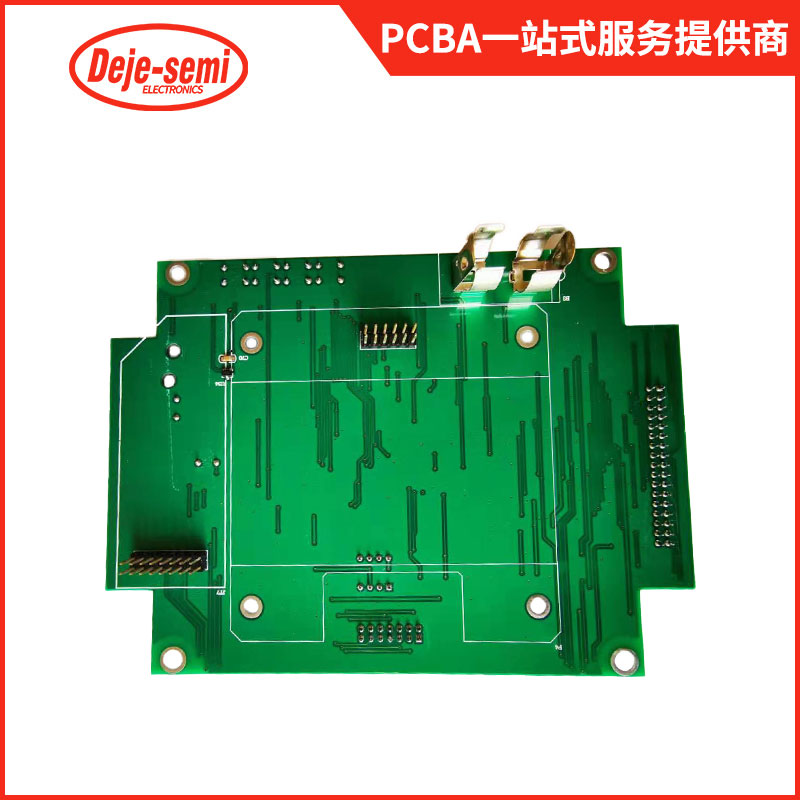

We provide PCBA processing services, starting from the production of PCB circuit boards, integrating PCB manufacturers (obtaining extremely strict certification of TS16949 in automobile industry), and paying attention to the quality of circuit boards and PCBA quality control system. We have been a sales agent for imported electronic components for 20 years. We have maintained long-term cooperation with well-known manufacturers at home and abroad to ensure the original factory original packaging and regular purchasing channels of components. In the production process of PCBA, Japan ChiJu and Tongfang solder paste is selected to ensure the reliability of welding. With the help of automatic printing machine, Yamaha high-speed mounter, medium speed machine mounter, reflow soldering of upper and lower 10 temperature zones, AOI automatic optical detector and ICT, the reliability and quality of electronic packaging process can be effectively guaranteed. In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers, using a variety of test racks for 100% batch testing, including access, noise, amplitude, signal, temperature, humidity, drop or the implementation of customer's detailed test plan. All efforts are aimed at becoming a fine PCBA manufacturer.