<del id="u0s0c"></del> Quality management of PCBA OEM is not only the lifeline of PCBA products, but also the first goal of Dejie electronics.

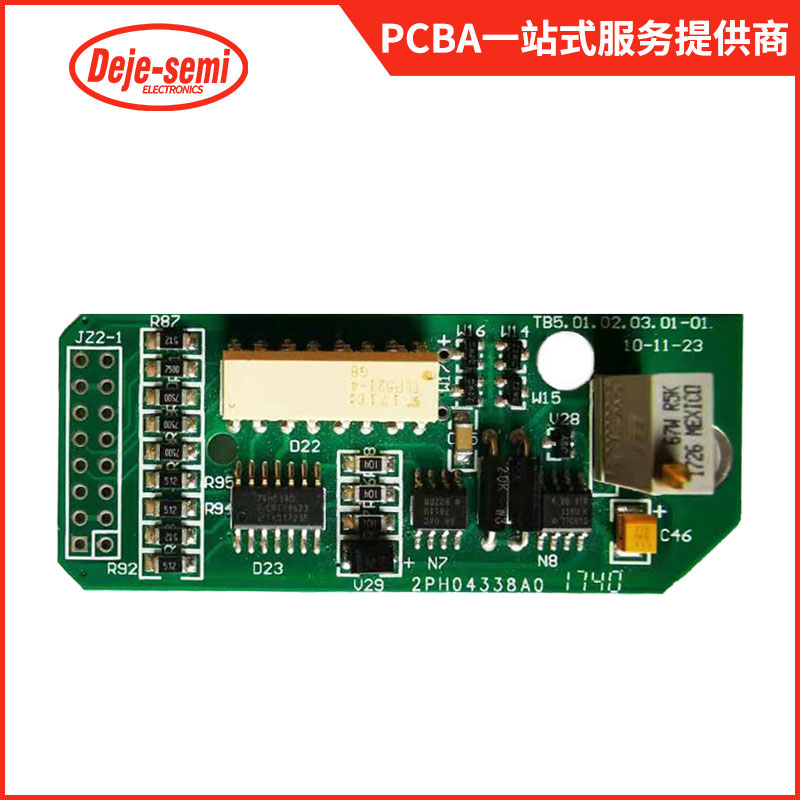

The idea of IPQC (in process quality control) is one of our highlights. In the production process of 20-30 circuit boards, setting the key points of IPQC can avoid the opportunity cost of subsequent processes caused by errors, facilitate the early detection and improvement of problems, effectively reduce the scrap rate, pass the benefits brought by low production cost to customers, and create continuous value for customers. In addition, the standard flying needle test, test bench test, AOI (automatic optical inspection) and other appearance inspection form a closed-loop quality inspection program combination, which is routinely implemented in our PCB Factory.

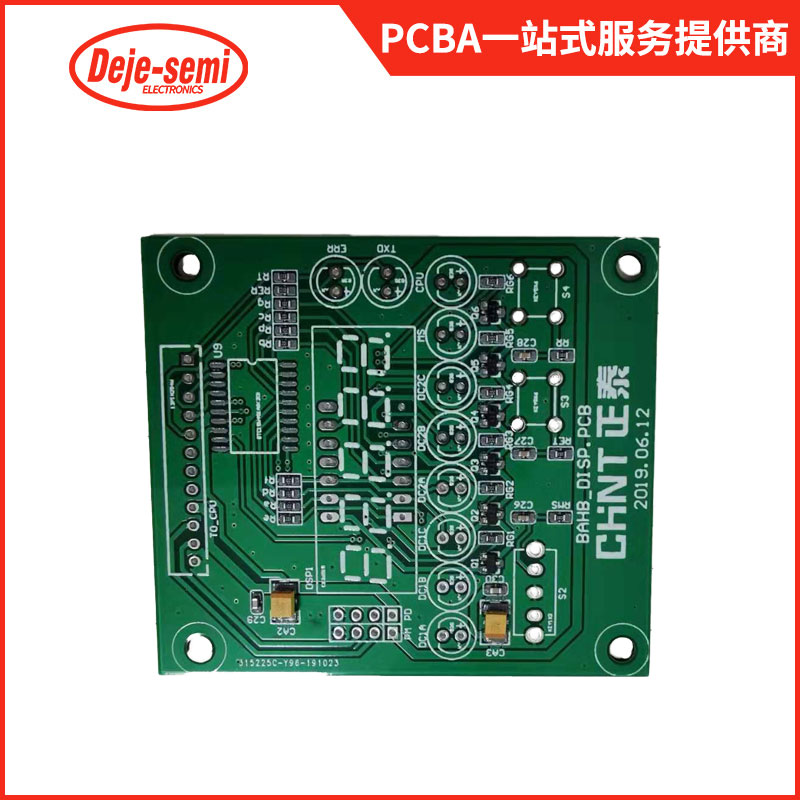

Dejie electronics strictly implements SOP specification, reshapes PCBA processing and electronic manufacturing process, simplifies procedures to the greatest extent, reduces human intervention factors and risks, integrates production and manufacturing orders delivered by customers into PDCA management system, and implements strict IPC electronic acceptance standards, so as to ensure high pass through rate and stability of customers' products. We have accumulated rich experience in SMT chip processing technology, and the common problems such as false soldering and lack of material can be effectively controlled, because we have adopted a set of standard management system based on international IPC and ISO9001 to ensure that the products are implemented according to the standard process, reasonable post setting and clear responsibilities. IQC and ipqc quality control in place.

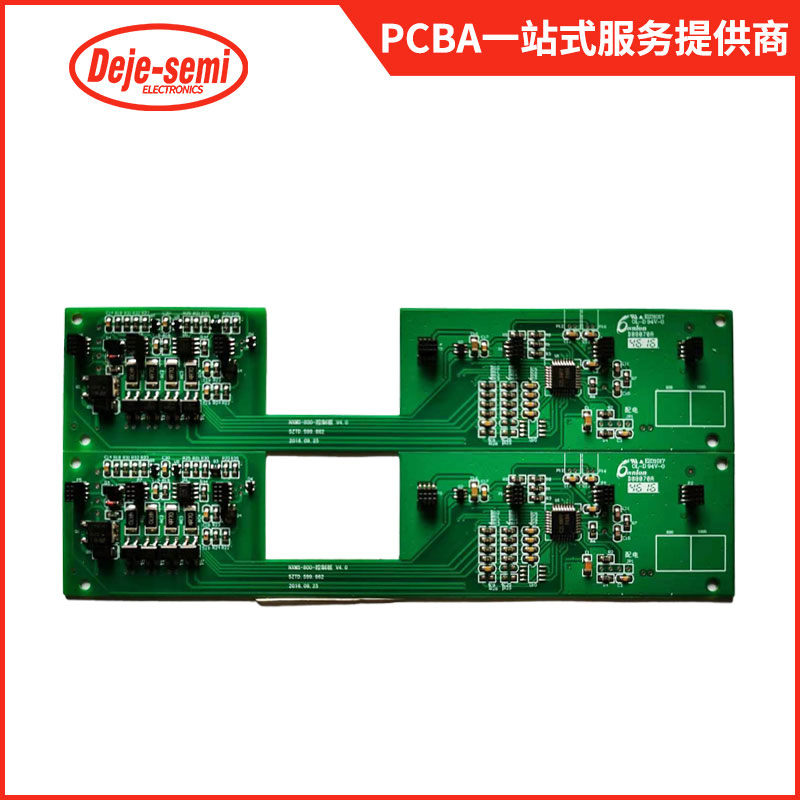

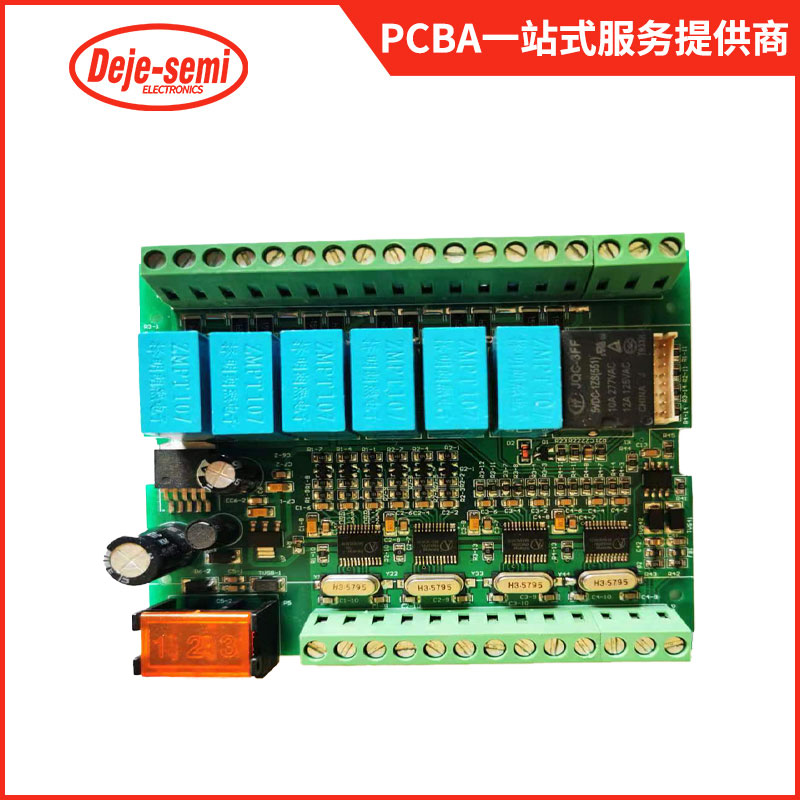

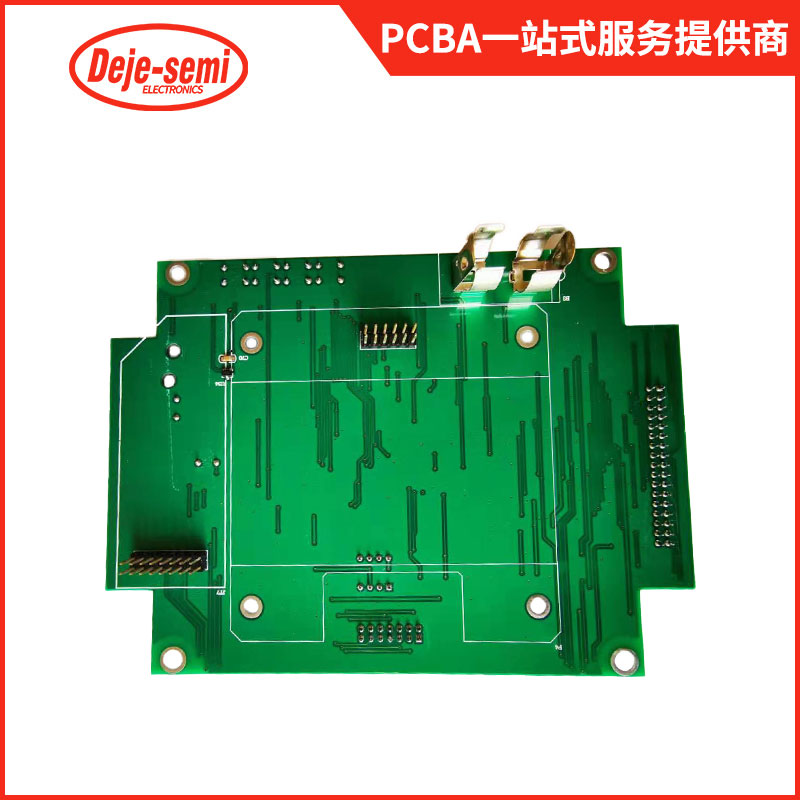

We provide PCBA processing services, starting from the production of PCB circuit board, our PCB Factory has obtained the extremely strict TS16949 certification in the automotive industry, focusing on the quality of circuit boards and PCBA quality control system. Due to more than ten years of experience in electronic components procurement, we have maintained long-term cooperation with large brands to ensure the original packaging and procurement channels of components. In the packaging process of components, Qianzhu and alpha solder paste are selected to ensure the reliability of welding. With the help of automatic printing machine, Panasonic, Yamaha full-automatic high-speed mounter, upper and lower eight temperature zone reflow soldering, AOI automatic optical detector, X-ray detector, etc., the reliability and quality of electronic packaging process can be effectively guaranteed. In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers, using a variety of test racks for 100% batch testing, including access, noise, amplitude, signal, temperature, humidity, drop or the implementation of customer's detailed test plan. All efforts of Dejie electronics aim to become a fine PCBA processing factory.