<del id="u0s0c"></del>

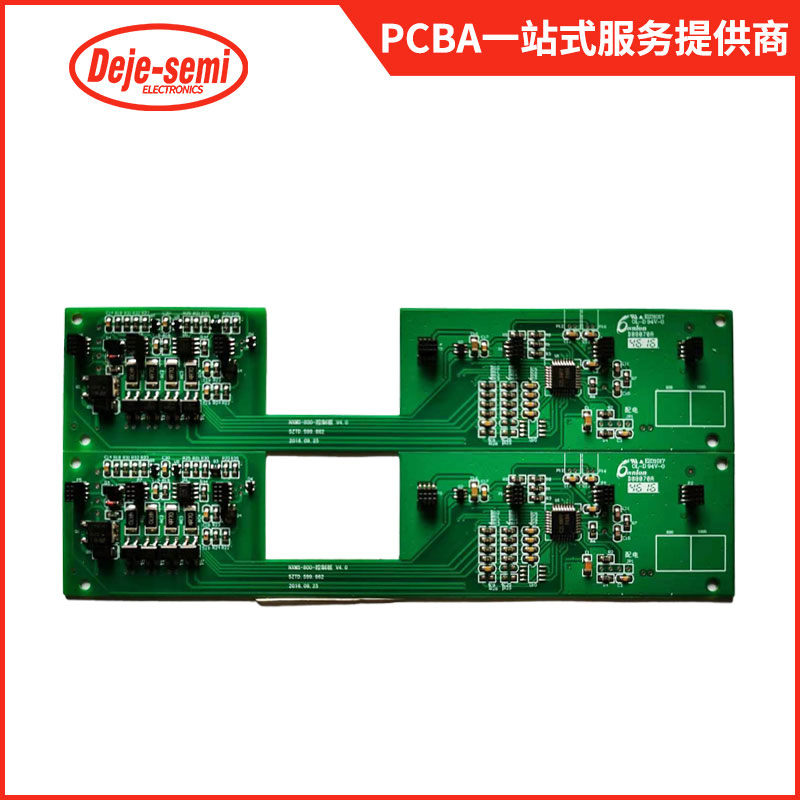

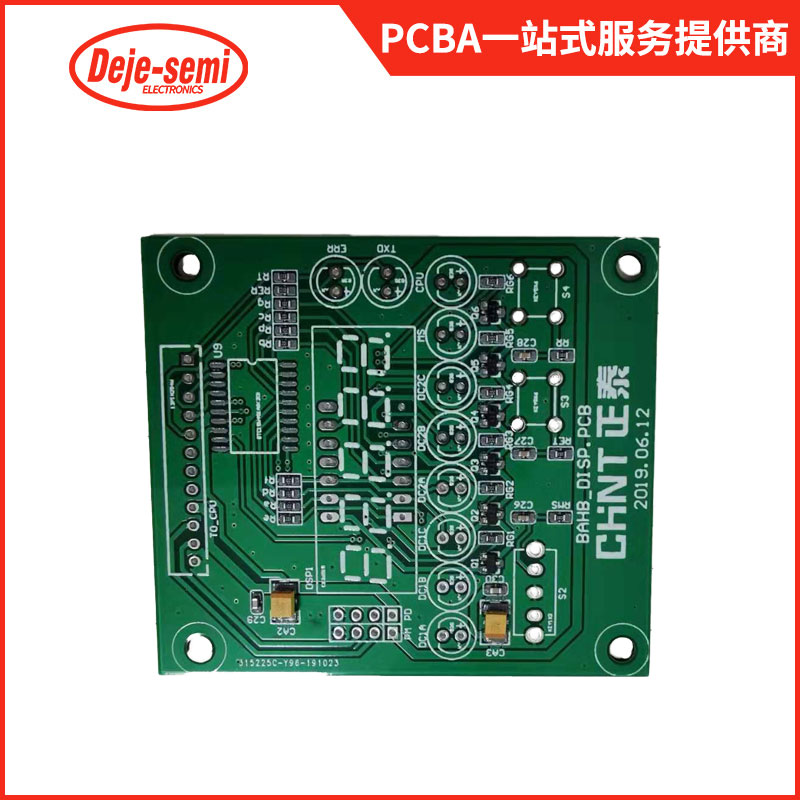

PCBA processing capacity

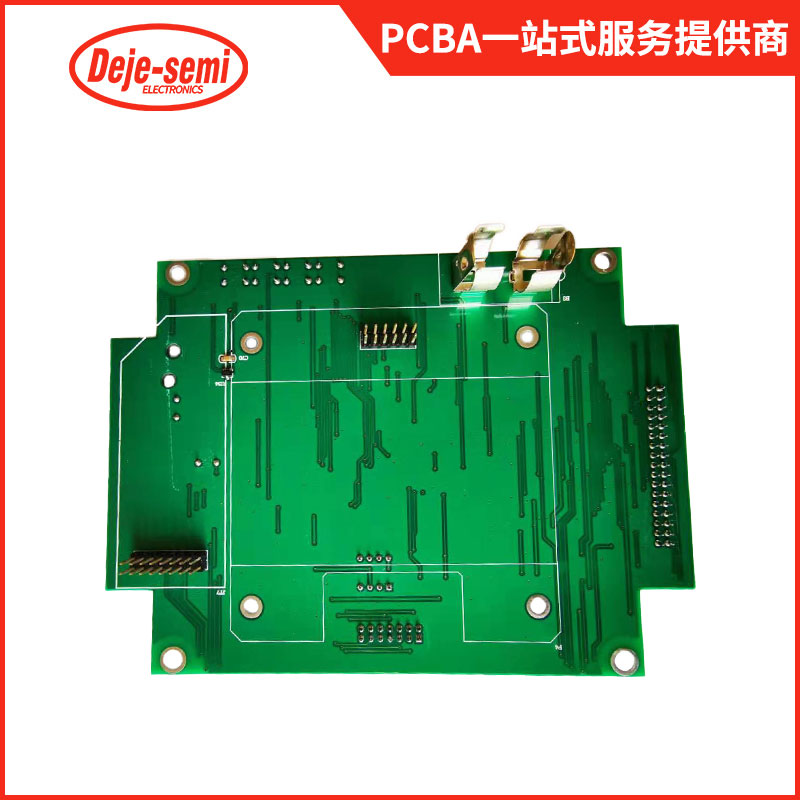

Dejie electronics has the ability of all-round and all-round PCBA OEM and material substitution. We focus on various PCBA processing, PCB manufacturing and SMT SMT placement services.

Dejie electronics has the ability of all-round and all-round PCBA OEM and material substitution. We focus on various PCBA processing, PCB manufacturing and SMT SMT placement services. With more than 10 years of experience in the whole process team and the most advanced production equipment, we can meet all your PCBA needs in a cost-effective way. Our PCBA production capacity includes but is not limited to the following list, because we constantly update our PCB manufacturing and SMT production equipment, and continue to develop technologies that can bring practicality to customers, so as to keep us at the forefront of the industry.

|

Project name |

PCBA processing capacity |

|

|

Delivery time |

We are proud of the rapid delivery of PCBA services. Our patch delivery time can reach 6 hours as soon as possible, and the regular expediting time is 24 hours to 48 hours. The delivery time of routine proofing is 3-4 days, and the batch delivery time is 5-7 days. All the above time is calculated immediately after all components and PCB materials are ready. |

|

|

Capacity |

SMT chip 4 million points / day, plug-in post welding 500000 points / day |

|

|

Component services |

Full set of substitutes |

Dejie electronics has a mature and effective component procurement management system, which serves PCBA OEM project with high cost performance. A team of professional purchasing engineers and experienced purchasing staff is responsible for the component procurement and management of our customers. Customers choose our full set of substitute materials, which greatly reduces the purchase cost and management cost, eliminates the trouble of multi-party communication, and improves the work effect. |

|

OEM only |

Relying on the strong purchasing management team and component supply chain, we are inclined to provide customers with a full set of PCBA OEM services. Of course, we are also willing to provide SMT SMT SMT processing services. Customers provide us with components and PCB smooth board, and we post solder. In order to ensure the quality of the finished products, we need to ensure that all PCBA mounting and customer supplied materials are packaged in a whole package, such as tray packaging and tape packaging. |

|

|

Partial substitution |

Some of the core components or special components are provided by customers. We are willing to provide substitute service for other components for customers. |

|

|

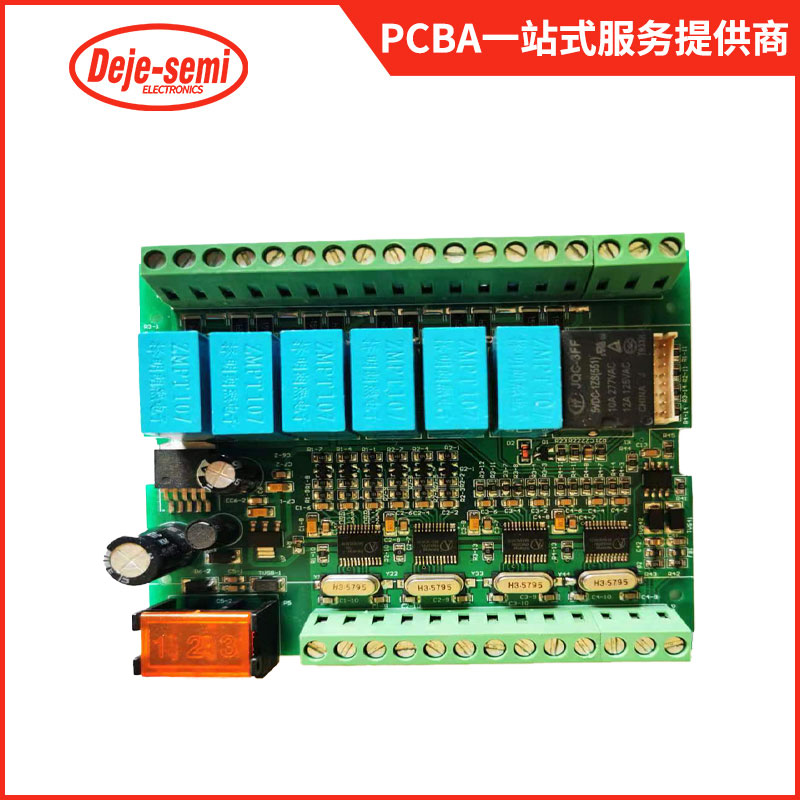

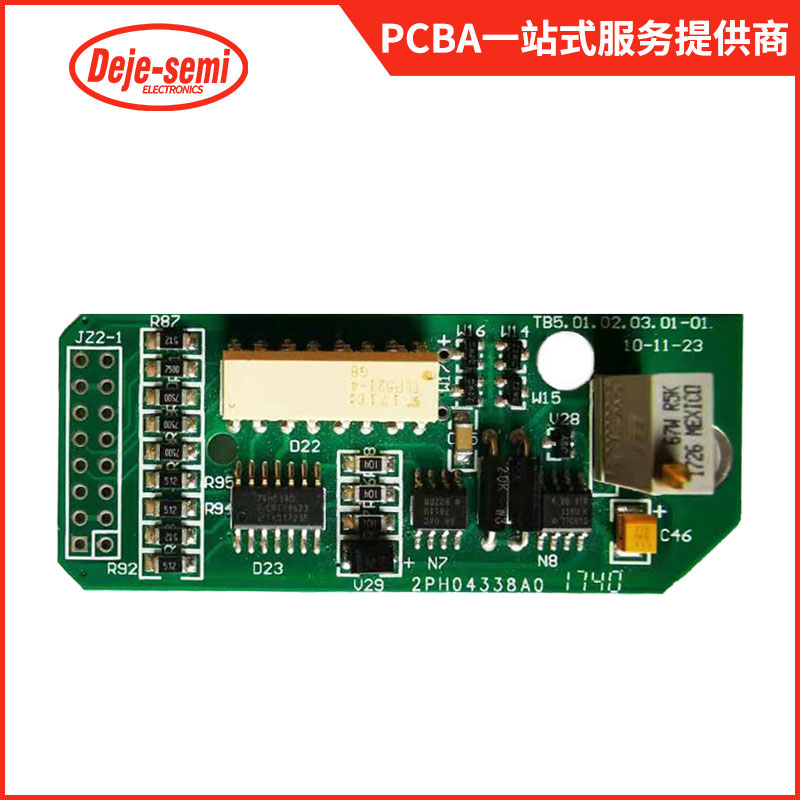

PCBA welding type |

We offer SMT, tht or both PCBA welding services. Of course, the double-sided patch is the most basic ability. |

|

|

Solder paste / wire / strip |

We provide customers with lead-free and lead-free (RoHS compliant) chip processing services. At the same time, we also provide customized solder paste welding service with different metal content according to customer requirements. We have long-term close cooperation with Qianzhu, alpha and other solder suppliers, only for higher quality demand, customers have demand, we can do it! |

|

|

Steel mesh |

We use laser steel mesh to ensure that the placement of small spacing IC and BGA components meets ipc-2 class or higher standards. |

|

|

Minimum order |

We start with 1 tablet, but we suggest that our customers produce at least 3 samples for their own analysis and testing. |

|

|

Element size |

?Passive components: we are good at mounting small components such as English 01005 (0.4mm * 0.2mm) and 0201 |

|

|

Component packaging |

SMT components we accept reel, cutting tape, pipe and tray can be packaged on machine. Post weld elements are accepted in bulk. |

|

|

Board size of SMT |

?Minimum plate size: 45mm x 45mm (plates smaller than this size need to be assembled. In order to improve efficiency, it is recommended to be greater than 100 mm * 100 mm) |

|

|

Types of pasteable PCB board |

PCB hard board (FR-4, metal substrate), PCB soft board (FPC), combination of hardware and software PCB |

|

|

File format |

File format BOM, PCB (Gerber file and most PCB design format file), coordinate file) |

|

|

Test |

Before delivery, we will apply various test methods to PCBA in or installed:

|

|

|

Repair & rework |

Our BGA repair service can safely remove the bad BGA such as dislocation, offset and false soldering, and paste it perfectly on the PCB. |

|